13.5-Mile 115kV Energized Line Rebuild

Located in Rhode Island

- Capability

- Distributed Power, Renewable & Industrial

- Completion 2024

Project Overview

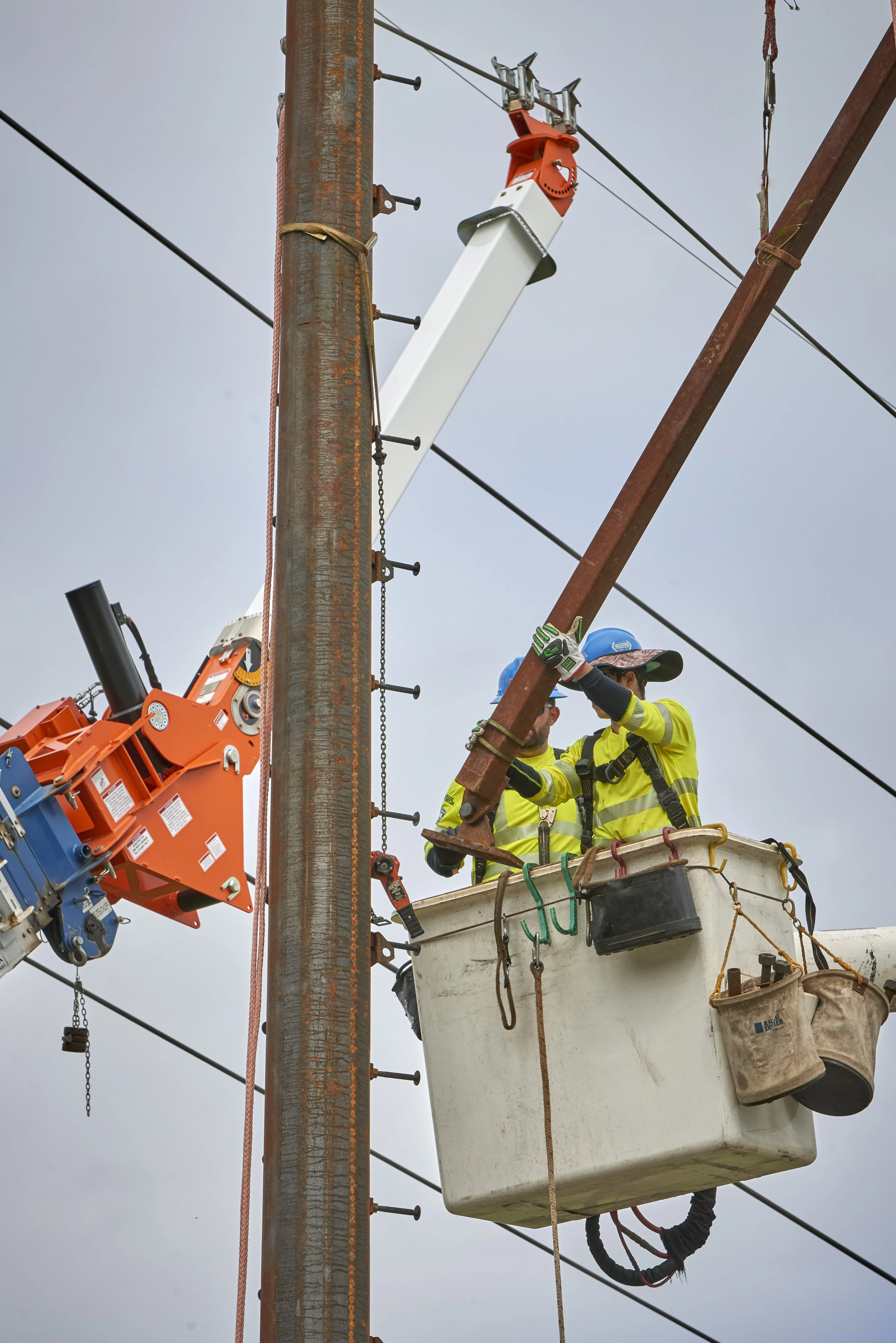

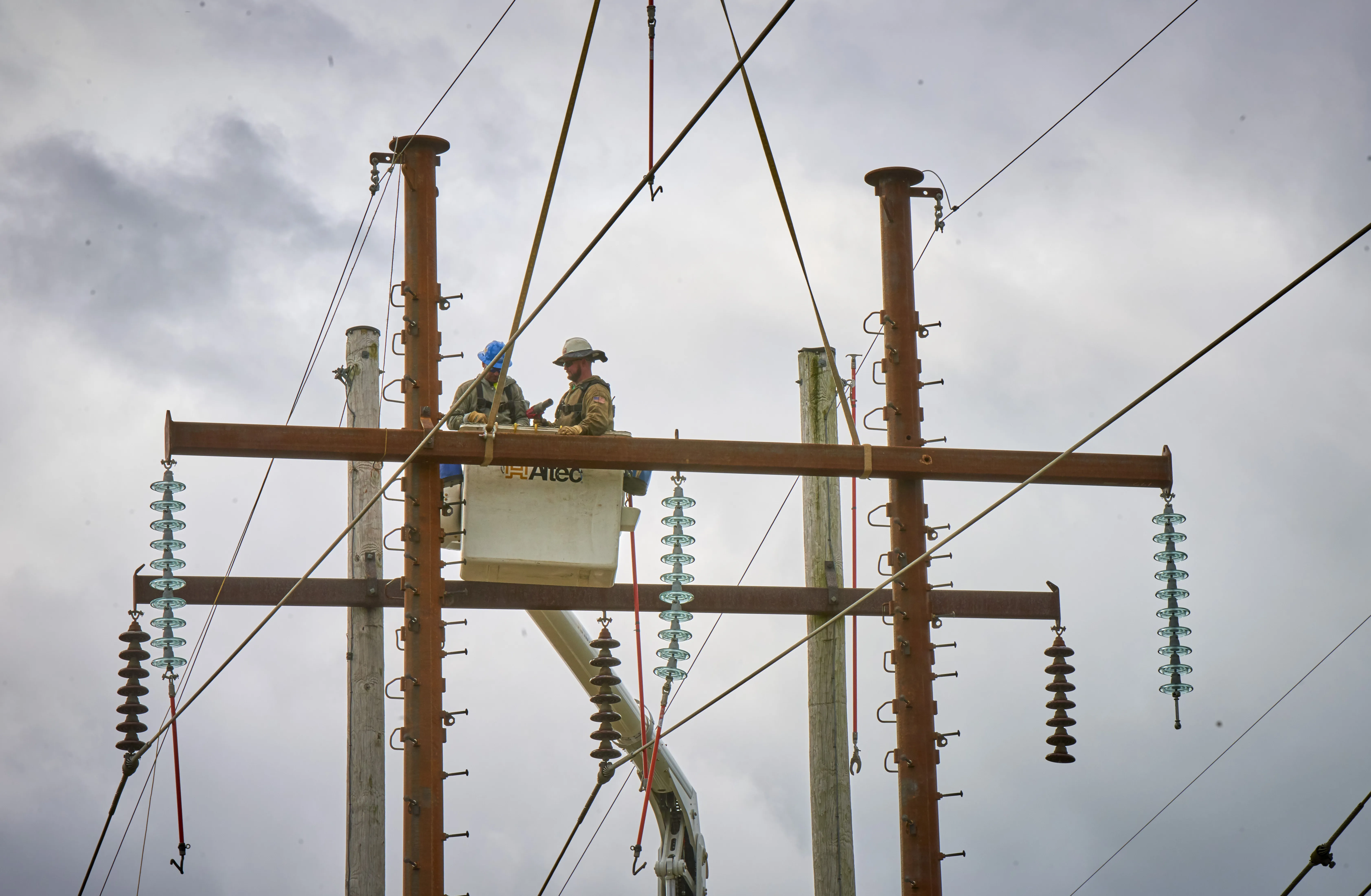

In 2024, we executed a 115kV energized line rebuild for our utility client in Rhode Island to support the anticipated increase in energy output from the Revolution Wind project. The work included drilling, foundations, environmental matting support services (tooling and equipment), and energized transmission work and reconductoring.

Project Overview

In 2024, we executed a 115kV energized line rebuild for our utility client in Rhode Island to support the anticipated increase in energy output from the Revolution Wind project. The work included drilling, foundations, environmental matting support services (tooling and equipment), and energized transmission work and reconductoring.