Cogen Upgrade Project

Located in New Jersey

- Capability

- Distributed Power & Data Centers

- Completion 2019–2020

Project Overview

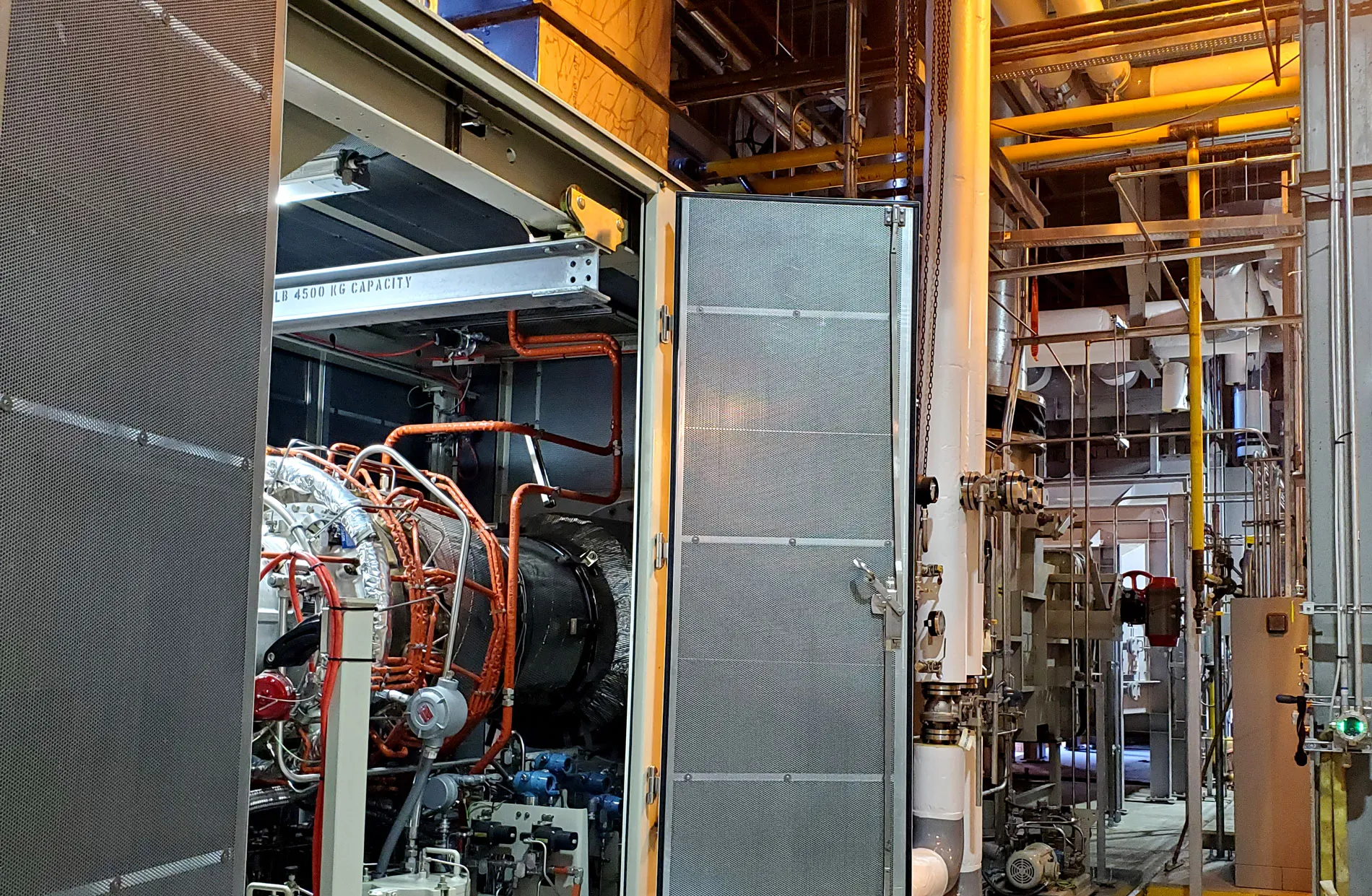

In New Jersey, the team worked alongside our joint-venture engineering partner to complete upgrades to three gas turbines and a hot water waste generator at an electrical generation site. Installing the upgraded units lowered the owner’s maintenance costs associated with the unreliability of older units and planned shutdowns, lessened the facility’s impact on the environment, and allowed the plant to perform more efficiently. The new units each produced 5.7 MW of electricity. The successful project completion was due to the efforts of our Heavy Industrial and Electrical Generation teams.

Project Overview

In New Jersey, the team worked alongside our joint-venture engineering partner to complete upgrades to three gas turbines and a hot water waste generator at an electrical generation site. Installing the upgraded units lowered the owner’s maintenance costs associated with the unreliability of older units and planned shutdowns, lessened the facility’s impact on the environment, and allowed the plant to perform more efficiently. The new units each produced 5.7 MW of electricity. The successful project completion was due to the efforts of our Heavy Industrial and Electrical Generation teams.