Delivering Turnkey Power Construction Solutions in the Ocean State

FROM GENERATION TO THE METER

The Opportunity

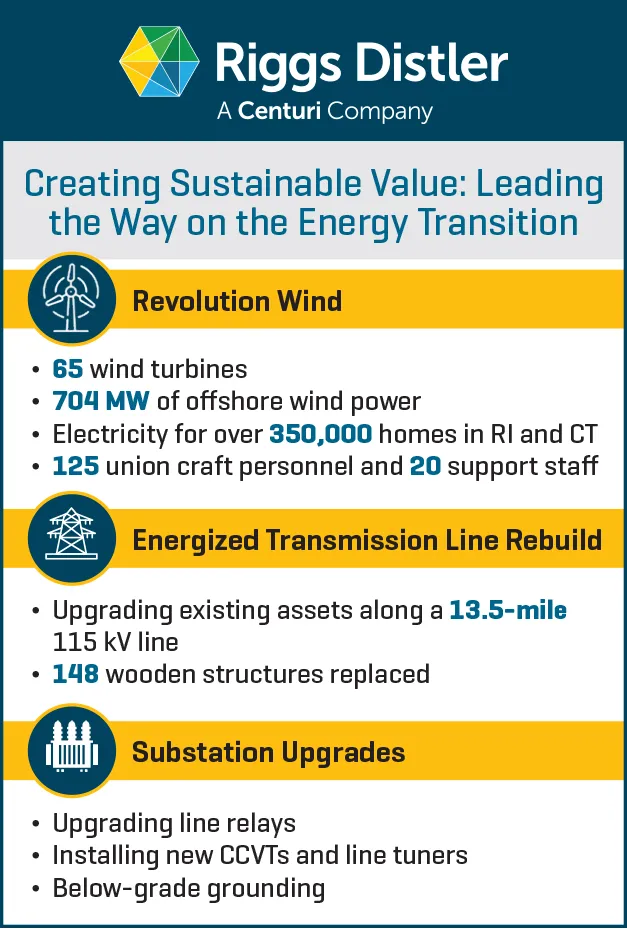

Leveraging a century of experience, Riggs Distler seamlessly integrates infrastructure projects, increasing the efficiency and safety of each to get the job done right, on time, and on budget- every time. In Rhode Island, Riggs Distler is working on three interconnected projects for the same host utility, showcasing our versatile capabilities. Moving towards the final stages of the project, we are constructing advanced foundation components for the Revolution Wind Farm, slated for deployment off the coasts of Rhode Island and Connecticut in 2025. Concurrently, we are involved in the reconstruction of a 13.5-mile 115 kV energized line and have secured contracts for upgrading four (4) Substations in the state. These interconnected projects reflect our comprehensive approach to infrastructure development from generation to the meter. To delve deeper into the details of each project and explore the synergies that drive their collective success, read on.

Revolution Wind

At ProvPort, Rhode Island, Riggs Distler is constructing advanced foundation components crucial for the Revolution Wind project including supported internal platforms, external working platforms, monopile doors, and anode cages. As general contractor for leading offshore wind developer Ørsted, Riggs Distler is blazing a trail as the first company to assemble wind components of this size and scale in the U.S. In doing so, we are building a domestic supply chain, creating jobs and economic development for local communities, and enabling a future powered by renewable energy.

The Workforce

The project has involved the deployment of 125 union craft personnel and 20 support staff. Crews are completing onshore construction, assembly, inspection, and delivery of the advanced foundation components for 65 offshore wind turbines.

The Work

The Work

Supported Internal Platforms (SIPs)

The SIP is inserted inside the monopile foundation offshore and is essential to the process of transmitting clean energy to the offshore substation, which will then travel to an onshore substation and become part of the electrical grid. The SIP houses all the communication components for each turbine as well as the entry point for the subsea cables and a variety of electrical equipment required for operations and maintenance of the turbine.

External Working Platforms

External concrete platforms are used for safe wind turbine access, operation, and maintenance. They include multiple systems to permit personnel and equipment access for offshore wind technicians.

MP Doors

MP Doors provide access to the SIP, inside the monopile foundation, from the External Working Platform.

Anode Cages

A sacrificial anode structure is installed as a means of cathodic protection. This approach uses a ring-like frame arranged around the monopile. The cage is installed offshore by slipping over the top of the monopile, prior to the installation of the external concrete platform. Because the anodes are cast of a less noble metal than the monopile, they corrode more readily, thus serving a sacrificial role.

Upon completion, Revolution Wind will feature 65 wind turbines, contributing a total of 704 MW of offshore wind power, with 304 MW allocated to Connecticut and 400 MW to Rhode Island. This renewable energy initiative is expected to provide electricity for over 350,000 homes in both states. In Rhode Island, once this windfarm comes online, our onshore transmission and substation work in the state will support bringing the power to the grid.

13.5 Mile 115kV Energized Line Rebuild

Riggs Distler is executing a 115kV energized line rebuild for our utility client in Rhode Island. Our team is upgrading existing assets along a 115kV line to support the anticipated increase in energy output from the Revolution Wind project. Work includes drilling, foundations, environmental matting support services (tooling and equipment), and energized transmission work and reconductoring.

PROJECT DETAILS:

Replace 148 current wooden structures with engineered light-duty steel H-Frame suspension and heavy-duty engineered steel dead-end structures

Replace existing 13.5 miles 795 ACSR with 795 ACSS

Replace existing steel shield wire with OPGW

Drill direct-embedded holes for new CMPs at each location for 127 structures

Install 47 concrete foundations for 19 new structures

PROJECT CHALLENGES

What sets this project apart, and poses a challenge, is the proximity of the 115kV line to two other energized lines –a 115kV transmission and a sub-transmission line – both running parallel to the 115kV line we are upgrading. Our selection by the host utility for this project was based on our proven reliability and track record as a contractor focused on delivering results. We demonstrated our capabilities by successfully executing environmental matting and transmission work on one of the adjacent lines several months prior to being awarded this project.

BUILDING ON EXPERIENCE

In 2022, our transmission and matting crews replaced the static wire with new OPGW wire on the parallel 115kV circuit via helicopter. This project had an aggressive schedule, requiring our crews to work 12-hour days continuously for 21 days to meet the deadline.

This experience provided us with valuable insights into the terrain, weather challenges, and client expectations. Our awareness of the growing service area demand underscored the importance of preventing any unplanned service interruptions to avoid disruptions in the community.

COMMITMENT TO SAFETY & THINKING AHEAD

As an Electrical Transmission and Distribution Partnership member since 2020, Riggs Distler consistently seeks opportunities to enhance safety within our workforce, for our clients, and the communities we serve. For those familiar with energized work, adhering to OSHA’s specific criteria is crucial when dealing with potentially hazardous energized parts.

As an Electrical Transmission and Distribution Partnership member since 2020, Riggs Distler consistently seeks opportunities to enhance safety within our workforce, for our clients, and the communities we serve. For those familiar with energized work, adhering to OSHA’s specific criteria is crucial when dealing with potentially hazardous energized parts.

The project scope includes the replacement of every existing wooden H-Frame suspension structure with the 115kV circuit in an energized state. Adjacent to the 115kV line we are working on is another 115kv line. For 8 miles, an additional energized 34kV sub transmission line runs parallel. While our line workers are well-versed in all energized construction methods including utilizing a robotic arm, bare hand methods, and hot stick techniques, ensuring each team member working on this project received updated training was our number one priority.

Prior to beginning the project, in collaboration with our Energized Services team at Centuri, we revised and distributed the Energized Transmission Manual, serving as a comprehensive guide for our crews. We then worked with a qualified trainer to internally train appointed team members. In addition, and to further ensure we were prepared for the task at hand, our leadership team brought in energized experts from LineWise to facilitate both classroom and hands-on training on specialized equipment. This training aimed to refresh our line workers on using phase lifter arms, ensuring a thorough understanding of the safe installation, operation, and stowing procedures of the equipment from the project’s outset.

By prioritizing the dissemination of up-to-date safety protocols, we ensure that each member is equipped with the necessary skills to execute their tasks safely. Ultimately, our commitment to providing the latest safety methods reflects our dedication to ensuring the successful completion of the project while prioritizing the well-being of our team, ensuring that everyone returns home safely to their families at the end of each workday.

UTILIZING THE LATEST TECHNOLOGY

UTILIZING THE LATEST TECHNOLOGY

When working in a confined workspace with a limited number of work pads in the right of way, the utilization of the robotic arm is critical to working safely. In situations where space constraints rule out the use of cranes, the robotic arm proves invaluable. This specialized arm allows the line workers to precisely manipulate energized phases in close quarters, facilitating a controlled environment for pole setting and conductor movement. Crafted from sealed fiberglass and equipped with a moisture-absorbing desiccant canister, the robotic arm provides an additional layer of protection. Incorporating such equipment significantly aids in time and resource efficiency throughout the project.

PROJECT PROGRESS

This energized transmission project is a little over halfway complete. Drilling and foundation crews have successfully drilled new direct embed holes and installed new CMP in the designated structure locations and all concrete foundations have been completed thus, paving the way for the transmission team’s upcoming structure replacements which are at 70% completion. Reconductoring and schedule adjustments have been a challenge for the team this year, necessitating weekly meetings to collaboratively find solutions and adhere to project timelines. Stay tuned for further updates once the project reaches completion.

Substation Upgrades

Riggs Distler’s Substation and Civil Groups have recently been awarded the first four (4) of many substation upgrade projects for our Rhode Island host utility. These substation enhancements are integral components of the energized transmission work outlined earlier. They will support the transmission and distribution of the green energy generated offshore by Revolution Wind and facilitate the interconnection of energy to the grid in Rhode Island. Crews will upgrade the protection and control systems within the substations, in addition to installing new foundations, below-grade raceways, grounding systems, and above-grade equipment. Additionally, we will be performing substation relay upgrades, transitioning from outdated relays to new Microprocessor SEL relays to enhance communication between substations. We will also provide removal and replacement of (5) 115kv circuit breakers and (4) associated disconnect switches. All foundations, conduit and below grade raceways will be replaced. The comprehensive upgrade also includes the enhancement of protection and controls. Construction on these projects is slated to commence later this spring.

ITS ALL CONNECTED

From Generation to the Meter: Riggs Distler is the Turnkey Construction Contractor for Today with a Focus the Future of Renewable Energy

Our ongoing work for the host utility is intricately linked to the Revolution Wind project, slated for installation off the coasts of Rhode Island and Connecticut, with power generation set to commence in 2025. As the primary construction contractor for Ørsted and Eversource’s Tier 1 Revolution Wind Project, Riggs Distler holds the distinction of being the first to undertake the construction of offshore wind advanced foundation components of this magnitude in the United States. In addition to providing construction solutions for Revolution Wind and contributing to reliability projects on transmission lines in Rhode Island, Riggs Distler also recently secured four (4) Onshore Substation projects. These interconnected projects, which play a vital role in bringing renewable wind energy from offshore to onshore through our work on Revolution Wind, enhancing transmission line reliability, and upgrading substations, underscore our commitment to supporting clients at every phase, ensuring the development of dependable infrastructure to support the future of clean energy.