New Jersey Landfill RNG Project

Project Overview

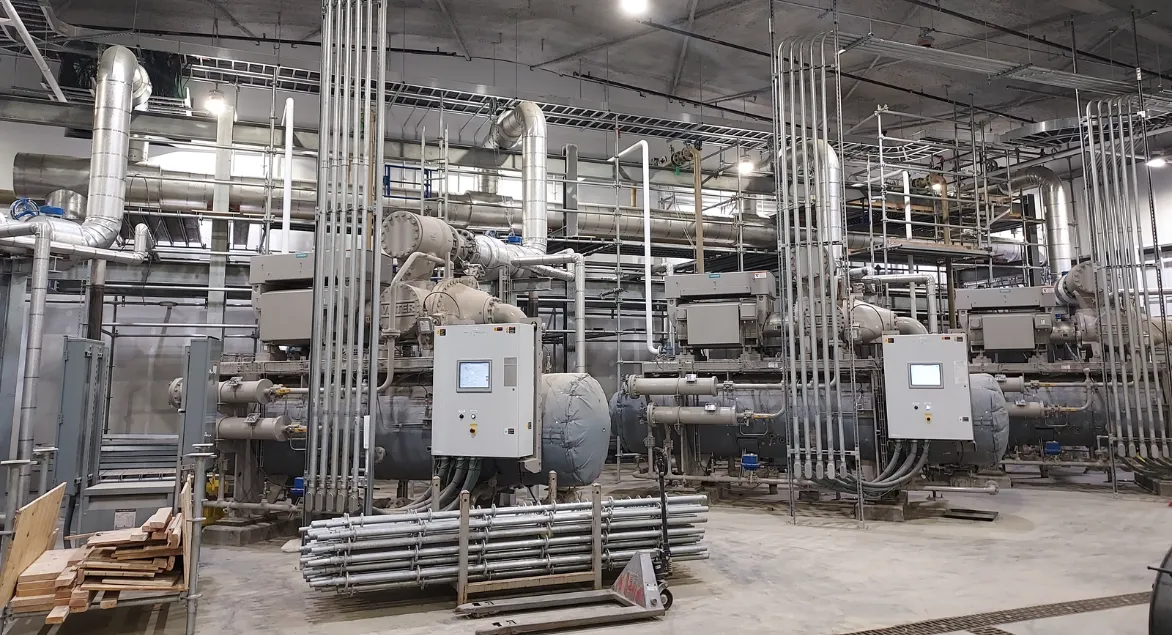

Riggs Distler’s Heavy Industrial and Generation (HIG) team self-performed the electrical ground-up installation of a new Renewable Natural Gas (RNG) Compressor Pumping Station at a major New Jersey landfill. The scope included full turnkey construction solutions including: mechanical, electrical, equipment setting, pipe fabrication and installation, painting, carpentry, scaffolding, and insulation. Electrical work featured building-wide cable tray systems, site-wide conduit installations, cable pulls, fire alarm systems, site lighting, and full electrical integration for gas monitoring and sensor systems.

At full capacity, the plant processes landfill gas at a rate of 6,500 CFM (cubic feet per minute), transforming otherwise harmful emissions into clean, usable energy for local consumption. Union trades from six different locals were engaged to execute the work across two shifts to meet the accelerated project schedule.

Challenges Overcome

Working in an active landfill required meticulous safety coordination and environmental controls. Our crews navigated limited workspace, ongoing landfill operations, and variable site conditions while maintaining an aggressive project schedule. Additionally, integrating new gas processing systems into existing infrastructure demanded precision planning and seamless collaboration across multiple trades.

Results Delivered

The Landfill Renewable Natural Gas project stands as a model of industrial sustainability and construction excellence. Riggs Distler delivered:

- A fully operational RNG plant under an accelerated timeline, meeting the client’s critical in-service deadlines

- Integration of six union trades and over 100 union jobs at project peak

- Solutions to overcome evolving engineering and equipment delivery issues with minimal impact to schedule or cost

- A high-quality facility with full electrical and mechanical integration that is now helping to convert 6,500 CFM of landfill gas into usable energy, reducing emissions and providing clean fuel to local utilities

Through this project, Riggs Distler has proven its ability to deliver complex, high-pressure, multi-discipline projects that support environmental responsibility and industrial innovation.

Check out this drone footage of the completed project:

Services

-

Mechanical

-

Electrical

- Equipment Setting

- Pipe Fabrication and Installation

- Painting

- Carpentry

- Scaffolding

- Insulation

Our Work Included

-

Installed process piping for gas collection and transport

-

Set and connected compressors and gas processing equipment

-

Installed and integrated electrical systems, controls, and instrumentation

-

Coordinated construction within an active landfill environment

-

Conducted testing and commissioning support for new systems