Revolutionizing Water Treatment: Implementing a Reverse Osmosis Plant in Philadelphia, Pennsylvania

Project Overview

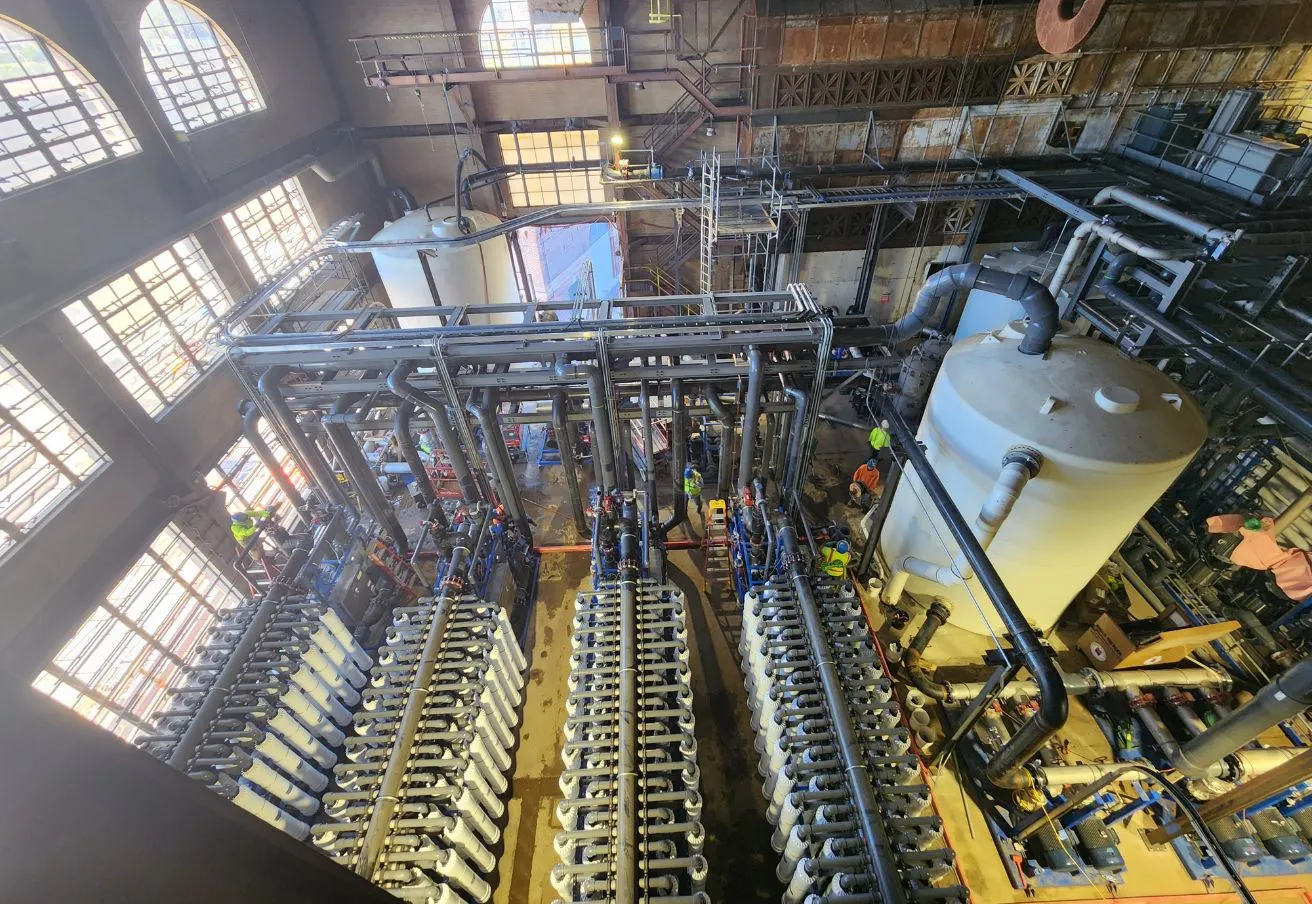

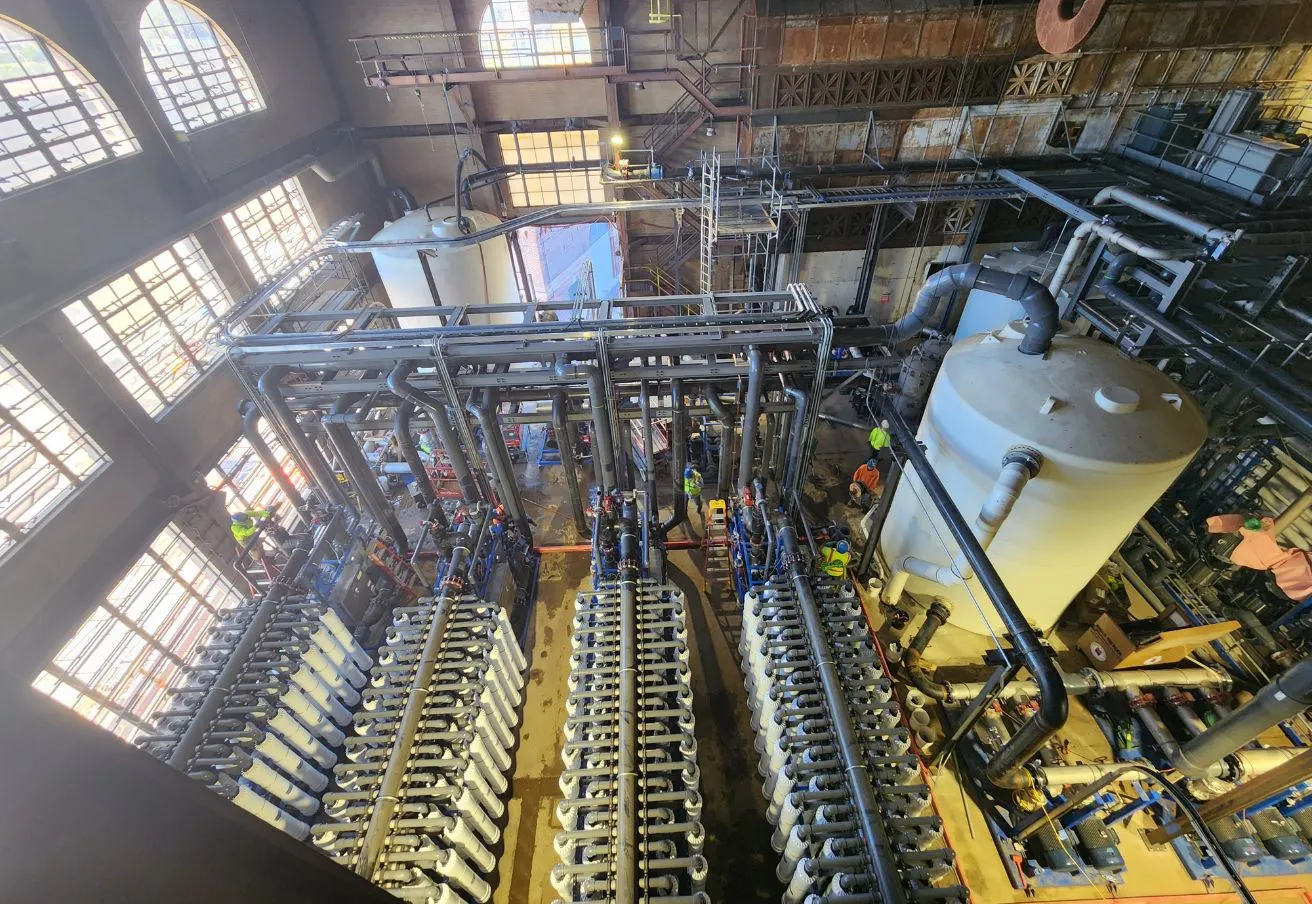

Riggs Distler’s Mechanical, Industrial Electric, and Heavy Civil groups partnered to successfully complete the construction of a new Reverse Osmosis Water Treatment Plant for our energy client in Philadelphia. The client sought to construct, own, and operate the reverse osmosis plant to supply filtered, deionized river water for use in its steam generation process. This was in an effort to reduce the high monthly cost of using city water.

Challenges Overcome:

The project presented significant challenges, as the new plant was constructed on an existing building that was over a century old. An extensive amount of existing equipment and piping required removal prior to beginning construction.

With the new equipment being installed in tight quarters, it was crucial for our team to plan thoroughly and work strategically. Our mechanical group utilized our design team to scan the entire building and used 3D modeling for equipment layout and production of isometric drawings. This allowed for a thorough understanding of the space and ensured that the new equipment would be installed in the most efficient and effective way possible.

Additionally, due to the current market, equipment deliveries – specifically electrical equipment – were very difficult. We experienced major delays in the switchgears, pumps, and VFD’s. To overcome this challenge, our team worked closely with our engineering partner in order to procure temporary equipment. This allowed us to continue with start-up and commissioning, ultimately getting the plant in service on time.

Services

- 3D Scanning

- Demolition of existing Turbine to open the entire floor for new RO Plant

- Custom fabrication

- Furnished and installed 5KV Feeders from the existing plant’s distribution to supply the new 5KV Switchgear

- Installed (2) 480v new Motor Control Centers and (2) 120/208V new Power Panels with Transformers

- Installation of new switchgears, conduit raceways, Heat Trace Control Panel, and Cable Tray Systems

Results Delivered:

Upon completion, the upgraded plant was capable of producing up to 2,000 gallons of demineralized water per minute. Riggs Distler’s Heavy Industrial group showed its expertise, skill, and ability to perform projects with a unified approach by utilizing all its divisions within the division, resulting in the successful completion of the project.

The successful implementation of this reverse osmosis plant greatly reduced the high cost our client spent on water in-take from the City of Philadelphia. This project serves as a prime example of Riggs Distler’s ability to deliver cost-effective solutions for our clients, while also ensuring the highest level of safety and quality. We are proud to have played a key role in our client’s success and look forward to continuing to provide innovative solutions for our clients in the future.